-

Highlight

280ton Ball Mill For Cement Grinding

,Q235A Ball Mill For Cement Grinding

,Q235A Roller Press Cement Mill

-

Housing MaterialQ235A

-

TypeVertical Type

-

Ground MaterialLimestone,

-

RollersFour Or Three

-

Place of OriginJIANGSU,CHINA

-

Brand NamePengfei

-

CertificationISO,CE,

-

Model NumberPFM

-

Minimum Order Quantity1 set

-

PriceUSD600000-USD6000000

-

Packaging DetailsAll the packing is suitable for the ocean transporting and inland transporting,1.The kiln shell is transported in 6 sections. 2.The supports is packed on the cushion.3. the small parts is packed in wooden box and iron frame.4.there will be shipping mark on

-

Delivery Time180 days

-

Supply Ability1 SET PER 180days

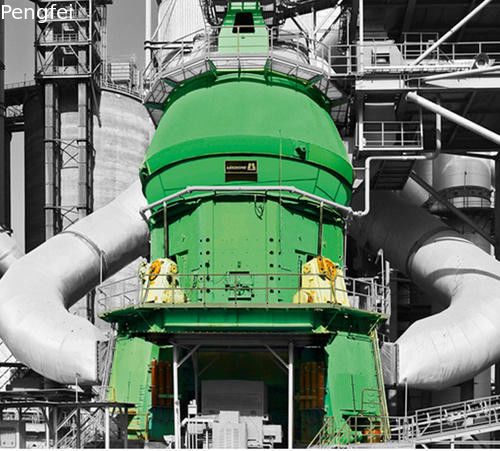

280ton Per Hour Ball Mill for Cement Grinding

280tons Per Hour Ball Mill For Cement Grinding

Brief Introduction of Jiangsu Pengfei Group Co., Ltd.

Location advantage: Jiangsu Pengfei Group Co., Ltd. is located in Nantong City which is in the north of Yangtze River delta economic metropolitan area. It connects Yellow Sea in the east and looks south to the Yangtze River. The company is the national famous building material machinery manufacturing and transporting base. The goods will be shipped to focus all over the world by the million tons of seagoing vessel will through the international Nantong Port and Shanghai Port. Ningqi Railway and Xinchang Railway connect here, and at the same time the coastal Highway and Haili Highway also link here. Because of its special harbor location advantages and manufacturing capacity, Pengfei Group has become the largest cement equipment manufacturing and exporting base in our national coastal areas.

Scope of business: The company has the great comprehensive ability to provide best quality services on turn-key basis with technology design, complete plant, erection and debugging, commissioning for the 10000t /d rotary kiln cement production enterprise. It can also undertake various projects abroad international bidding projects. It supplies complete equipments and technical services of grinding, calcination, crushing, dust collecting, conveying and lifting for the metallurgy, the chemical industry, the electrical power, the mine, the environmental protection enterprises, etc.

Market position:The total amount in the cement machinery industry is second rank among the same business, and first in Jiangsu Province. The products have been exported to Germany, Russia, Brazil, Egypt, Iran, Bangladesh, Pakistan, Turnkey, Myanmar, Vietnam, Columbia, Bolivia, South America, etc.

Company instruction: Jiangsu Pengfei Group mainly engages in the design, manufacturing, selling of complete set of equipment for the building material machinery, the environmental protection machinery, the metallurgical machinery and the chemical machinery industry, supplying the complete set of machinery and electrical equipment, installation and debugging, as well as contracting the turn-key basis project and the relevant technical service.The company has won the titles of Chinese leading enterprise in cement machinery industry, Jiangsu Credible and Trustworthy Enterprise and Jiangsu AAA grade credit enterprise. Its leading products have got Chinese famous brand products titles and “Pengfei” trademark also has been awarded “China Famous Trademark”. The company covers an area of 350,000m2 and it has 0.82 billion RMB of total assets. There are 450 engineers and technicians. The company has the six subsidiary companies such as the mechanical plant, electronic plant, casting plant, installation plant, the new type building materials plant, etc.The company has the mechanical processing capacity of 300,000t/y; its rotary diameter and gear hobbing diameter are 10m as well as the diameter of the annealing furnace is 6.5m; the maximum hoisting capacity is 400t, own CK52130x50/260(φ13m)vertical lathe,DVT1000x40/200(φ10m)vertical lathe,W11-120X3200(120mm thick 3200mm wide)steel plate rolling machine, C6070x21(φ7m,21m length)shell lathe, C6070x25(φ7m,25m length) shell lathe,C6070x15(φ7m,15m)shell lathe andφ7mx21m annealing furnace and etc. so the company can meet the manufacturing requirements of the rotary kiln and ball mill below φ6m. The large-sized pre-heater, rotary kiln, tube mill, vertical mill, cooler and other main machinery is completely researched, developed and manufactured by Pengfei Group itself. The company has assumed the dual role of supplier for the turn-key services and supplier for main equipments. After obtaining signing right and management qualifications of foreign project-contracting, Jiangsu Pengfei Group Co., Ltd actively develops the international business of project contracting, contracts construction and installation project as well as international bid project of cement, metallurgy, chemical machinery and equipment , at the same time dispatches the needed labors that the above mentioned foreign projects needed. Pengfei Group completed to manufacturing the main machines of Pakistan PLC 3000t/d cement production line for Hefei Cement Research & Design Institute successfully, and then got the business to manufacturing the main machines for Pakistan PLD, PLE and PLF Production Line. The company has taken on the complete project of eight cement production lines like Myanmar Thayet, Dragon, Triple A, King Elephant and Tiger Head Cement Plant, as well as the business to manufacturing the rotary kiln and cement mill for two 2500t/d cement production lines of Vietnam Kaisa Cement Plant. Pengfei Group has contracted the complete set of 1500t/d cement production line with Africa Rwanda company, and the project includes the process from the limestone crushing to the finished cement products, the electrical automation design, the equipments for the whole factory as well as the services of installation & debugging, personnel training, etc. At the same time the company implements the turn-key basis project of 2500t/d cement production line for Russia Volga Cement Plant.

Our board chairman and general manager, Mr. Wang Jia’an, warmly welcome all the overseas experts, colleagues and friends to come to our company, and survey and discuss about cooperation business and make great future together

OUR COMPANY IS MAINLY PRODUCE CEMENT MAKING MACHINERY,LIKE BALL MILL,ROTARY KILN,ROLLER PRESS,BAG HOUSE,ESP AND ETC

1.General Condition,,,

Model HRM&Model PRM roller mills are new equipment designed by digesting and assimilating advanced technology introduced from other countries.it through grinding rollers to roll and press the materials(0-40mm)on the rotating grinding pan with pressure and grind them to be reached up to the relevant finess.it has good advantages of high griding efficiency.big drying capacity.product finess is easy to be adjusted.low noise,low power consumption,simple process flow.low abrasiveness,operating cost saving and etc.

under the same process conditions and rotating speed.grinding pan diameter material level.grinding roller pressure are all the same,grinding efficency of Model PRM roller mill can be raised more than 30%,average power consumption can be saved about 8.2%,and impact vibration of the overall unital could be obviously reduced.

With international advanced technology and national leading manufacturing quality.it has passed the ministry-level test and listed as state level new preouct in 1995

2.The technical parameter

1.The inlet size is less than 80mm

2.The permited inlet moisture is 6%.

3.The mill speed is 29.75r/min

3.The specification of roller mill

| No. | Instruction of parameter | Unit | Technical parameter | Remarks |

| Vertical Mill | set | 1 | ||

| Type | VRM5341C | |||

| Ground material | Clinker | |||

| Inlet material size | mm | ≤50 | ||

| Material moisture | % | ≤7 | ||

| Product finess | ≤60 microns | Clinker+gypsum and other mixed material | ||

| Product moisture | % | ≤0.5 | ||

| Capacity | t/h | 160 (4200cm2/g) | ||

| 200 (3200cm2/g) | ||||

| Inlet air temperature | °C | <300 | ||

| Gas temperature outlet of mill | ℃ | 90~105 | ||

| Inlet air pressure | pa | ~-500 | ||

| Outlet air volume | m3/h | 480000 | ||

| Outlet air pressure | Pa | -4000~-5500 | ||

| Material feeding system | Feeding from one side and material falling from center | |||

| 1 | Separator | |||

| 1.1 Rotor of separator | ||||

| Speed adjusting range | r/min | 60~160 | ||

| Vane material | UP wear resistant plate | |||

| Blade quantity | 196 | |||

| Useful life | h | >15000 | ||

| Rotor diameter | m | Ø4.6 | ||

| Total height of rotor | mm | 2600 | ||

| Steel plate thickness of housing | mm | 25 | ||

| 1.2 Rotor bearing of separator | pcs | 2 | ||

| Lower bearing type | 23134CC/W33 | |||

| Upper bearing type | 29434E | |||

| Manufacture | SKF | |||

| 1.3 Drive unit of separator | ||||

| Speed adjusting way | Frequency conversion | |||

| Motor type | YVP355M-4 | VVVF | ||

| Power | kW | 250 | ||

| Voltage | V | 380 | ||

| Speed | r/min | 1450 | ||

| Manufacture | Siemens of China | |||

| Insulation grade | IP54 | |||

| Gear box type | B2SV09-9-B | |||

| Gear ratio | 8.8 | |||

| Permitted input power | kW | 450 | ||

| Manufacture | FLENDER of China | |||

| 2 | Roller unit | |||

| 2.1 Roller | ||||

| Quantity | pcs | 4 | ||

| Diameter | mm | 2400 | ||

| Width of roller | mm | 850 | ||

| Shape | Tyre shape | |||

| Roller assembly weight | t | 28.7 | ||

| Inspect system | Oil cylinder for auxiliary repair | |||

| 2.2 Roller tyre | ||||

| Material | ZG20SiMn+ surface hardfacing | |||

| Hardness | HRC>58~62 | |||

| Useful life | h | >2,000 | ||

| 2.3 Roller shaft | 40CrNi | Tempering and quenching | ||

| 2.4 Roller bearing | ||||

| Bearing type |

BC-6104 480×855×270 |

|||

|

BT2-6104 480×890×390 |

||||

| Useful life | h | >35,000 | ||

| Allowable max. temperature rise of bearing | ℃ | 80 | ||

| 2.5 Sealing air fan | ||||

| Type | 9-28ⅠNo4.5A-8 | |||

| Quantity | pcs | 1 | ||

| 2.6 Roller bearing lubrication | ||||

| Lubrication type | Circulating oil | |||

| Type of lubrication oil station | XRZ-2×16-2×10 | |||

| Qty | 2pcs | |||

| Oil pressure | MPa | 0.4 | ||

| Flow rate | l/min | 20 | ||

| 3 | Grinding table | |||

| 3.1 Table body | ||||

| Material | ZG270-500 | |||

| Nominal diameter | mm | 5300 | ||

| Speed | r/min | 22.6 | ||

| Height of dam ring | mm | ~200 | ||

| 3.2 Liner of grinding table | ||||

| Material | ZG20SiMn+ surface hardfacing | UP | ||

| Hardness | HRC>58~62 | |||

| Useful life | h | >2,000 | ||

| 4 | Upper housing | |||

| 4.1 Housing | Q235-A | |||

| 4.2 Liner inside the housing | Q235-A | CHP 6mm | ||

| Useful life | h | >20,000 | ||

| 4.3 Inspection door | ||||

| Quantity | pcs | 2 | ||

| 5 | Rocker | |||

| 5.1upper rocker+ lower rocker | ||||

| Quantity | group | 4 | ||

| Material of rocker | ZG35+Q235 | |||

| Material of rocker shaft | 40Cr | Tempering and quenching | ||

| 5.2 Rocker bearing | ||||

| Quantity | pcs | 8 | ||

| 6 | Frame part | |||

| Frame | pcs | 4 | ||

| Connecting bridge | pcs | 4 | ||

| Base of support | pcs | 1 | ||

| Base of gear box | pcs | 1 | ||

| 7 | Main drive | |||

| 7.1 Main motor | ||||

| Type | YRKK900-6 | |||

| Rated power | kW | 4200 | ||

| Output speed | r/min | 990 | ||

| Manufacture | TECO | |||

| Insulation grade | IP54 | |||

| href="javascript:void(0);" Rated voltage | kV | 10 | ||

| Rated frequency | Hz | 50 | ||

| Power factor (cosj) | 0.866 | |||

| Cooling mode | IC611 | |||

| Type of lubrication oil station | XRZ-25 | |||

| Oil pressure | MPa | 0.4 | ||

| Flow rate | L/Min | 25 | ||

| High speed coupling | ||||

| Type | No | |||

| Connecting method | Diaphragm flexible connecting | |||

| Qty | 1 | |||

| 7.2 Main gear box | ||||

| Type | MLX450 | |||

| Rated power | kW | 4500 | ||

| Gear ratio | 43.7 | |||

| Measuring temperature point for Input shaft | pcs | 2 | ||

| Vibrator(yes/No) | yes | |||

| Output speed | rpm | 22.6 | ||

| Transmission power | kW | 4500 | ||

| Thrust bearing | Plane shaft bush | |||

| Lubrication oil station | ||||

| Type | XGD-C250/1250 | |||

| High pressure pump | ||||

| Qty | 4 | |||

| Oil pressure | bar | 315 | ||

| Flow rate | L/Min | 250 | ||

| Motor | kW | 4×22 | ||

| Low pressure pump | ||||

| Oil pressure | bar | 4~6 | ||

| Flow rate | L/min | 1250 | ||

| Motor | kW | 2×22 | ||

| Volume of oil tank | m3 | 10 | ||

| Heater | number | 6 | ||

| Rated power | kW | 8×6 | ||

| Temperature detector | ||||

| Type | PT 100 | |||

| Temperature monitor | PLC Liquid touch screen | |||

| Type | TP277-6 | |||

| Manufacture | Nanjing high speed gear manufacturing Co., ltd. | |||

| 8 | Hydraulic system | |||

| Type | HY53-1000AI-W | |||

| Pressure (Normal/Max) | MPa | 8~12/16 | ||

| Flow rate ((Normal/Max) | l/min | 63/63 | ||

| Power (Normal/Max) | kW | /18.5 | ||

| Rated power | kW | 18.5 | ||

| Volume of oil tank | L | 1000 | ||

| Main hydraulic element | Italy ATOS | |||

| Control method | Long distance | |||

| 9 | Hydraulic system of roller | |||

| 8.1 Hydraulic cylinder of roller | pcs | 4 | ||

| 8.2 Hydraulic station of roller | pcs | 1 | ||

| 8.3 Roller swing cylinder | pcs | 1 | ||

| Type | Movable | |||

| 10 | Water injection of mill | |||

| Nozzle | pcs | 4 | ||

| 11 | Rotary air lock feeder | |||

| Type | ф1400x1500 | |||

| Quantity | pcs | 1 | ||

| Speed | rpm | 6 | ||

| Motor power | kW | 11 | ||

| 12 | Electrical control system | |||

| Low pressure control cabinet | Pcs | 2 | ||

| Control content | High pressure oil pumps 4 sets for lubrication, Low pressure oil pumps 2 sets, roller oil pump 8 sets; hydraulic oil pumps 2 sets; oil pumps for motor lubrication oil station. 6 groups electrical heater;air lock valve 2 sets; 1 pcs frequency control cabinet of seperator | |||

| Housing type | GGD | |||

| Main electrical brand | Schneider | |||

| PLC Control cabinet | Pcs | 1 | ||

| Type | Simens S7-300 |

Workshop ![]()

Certificate![]()