-

Highlight

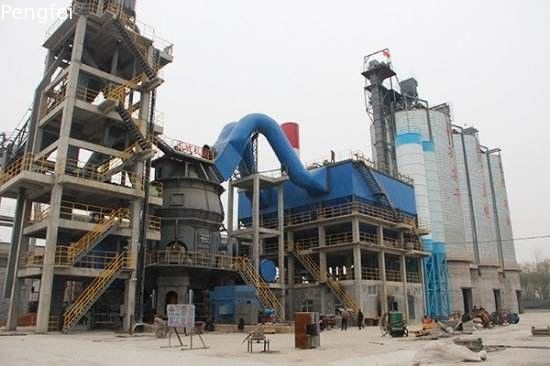

800tpd Cement Rotary Kiln

,Portland Cement Rotary Kiln

,ISO Portland Cement Plant

-

ProcessDry Process And Wet Process

-

Automatic LevelCompletely Automatically

-

Control MethodAutomatically Control

-

Voltage380V,10kV,6.6kV,11kV

-

Workign Days330 Days

-

Working Hours24 Hours

-

ColorAs Per Your Requirements

-

Working Rate99%

-

Place of OriginJiangsu

-

Brand NamePengfei

-

CertificationCE,ISO

-

Model Number1000tpd

-

Minimum Order Quantity1 set

-

PriceUSD8000000-USD16000000

-

Packaging DetailsAll the packing is suitable for the ocean transporting and inland transporting,1.The kiln shell is transported in 6 sections. 2.The supports is packed on the cushion.3. the small parts is packed in wooden box and iron frame.4.there will be shipping mark on

-

Delivery Time360 days

-

Payment TermsL/C, T/T

-

Supply Ability1 SET PER 360 DAYS

800tpd ISO Dry Process OPC Cement plant cement production line

WELCOME TO JIANGSU PENGFEI GROUP CO.,LTD

800tpd ISO Dry Process OPC Cement plant cement production line

Development goal

|

The main equipments for Kiln

|

Firing kiln end

|

Five-stage cyclone pre-heater C1: 2-Φ3800 C2: Φ5400 C3: Φ5400 C4: Φ5800 C5: Φ5800 KSF Decomposing furnace |

|

High-temperature fan: High-temperature fan (with governing fluid coupling) Model: W6-2×39-2No21.5F Volume: 255000m3/h Full pressure: 7100Pa Gas temperature: 350℃(Max. 450℃) |

|

| Waste gas treatment |

BS930 electric dust-collector BS930 Specification: 26/12.5/3×8/0.4 Handling blast volume: 300000m3/h Smoke and gas temp.: 120℃ (Max. 300℃) Inlet dust density: 80g/Nm3 Outlet dust density: <100mg/Nm3 Dust collection efficiency: 99.875% Gas dew point : over 47℃ |

|

Conditioning tower Specification: Φ6.5×26m Volume: 152700~223600m3/h Inlet air temp.: <400℃ Outlet air temp: <150℃ Water-spraying volume: 2.4~13m3/h |

|

|

Waste gas fan Model: Y4-73№25D Volume: 280000 m3/h Full pressure: 1700 Pa |

|

| Kiln outlet |

Grate cooler Model: LBTF1000 Capacity: 1000t/d Inlet temp.: 1400℃ Discharging temp.:Ambient temp.+65℃ |

|

BS930 electrical precipitator BS930 Model: 18/7.5/3×9/0.4 Volume: 180000 m3/h Electric field area: 51m2 Designed pressure设计: -2000Pa Dust collection efficiency: 99.875% |

Maching capacity

![]()

Coal homogenization

Raw coal is unloaded directly to the pit after coming into plant, and then sent to raw coal preblending stockpile via apron feeder, belt conveyer, elevator and belt conveyer with discharging trolley, or firstly unloaded to open-air stockpile, and then conveyed by forklift to receiving pit subject to inform, at last, it is conveyed to raw coal preblending stockpile through apron feeder, belt conveyer, elevator and belt conveyer with discharging trolley. The blended raw coal is sent to raw coal bin through forklift and belt conveyer.

Raw material proportioning silo and conveying

Raw material proportioning silo is composed of two concrete silos and three steel slab bins, and be measured by variable speed belt scale. Limestone silo consists of two Φ12m concrete silos, used for storage and proportioning. The proportioning bins is Φ6m,Φ6m and Φ6m respectively for clay, sandstone and iron ore.

Raw mill & waste gas treatment at kiln inlet

Proportioned raw material will be fed onto the air swept drying mill with size of Φ3.8×8.6m. In the process of rotating, raw meal will be raised by material raising device in the raw mill and sufficiently contact with hot gas from high-temperature fan at kiln inlet. By this means, raw meal will be dried. Dry raw meal is ground in the mill. Then the raw meal will fed onto high efficiency separator. Fine powder will be fed onto the raw meal-homogenizing silo via electric flap valve and air slide while coarse powder returned to the mill via electric flap valve and air slide. Hot gas from preheater goes through humidification tower and high-temperature fan and then divides into two parts, one part goes directly to electric dust collector, and the other part goes to raw mill head, and then 1/8 of this part goes to mill end. Waste gas out of mill firstly goes through high efficiency separator and raw mill fan (with inlet regulation valve), and joins the waste gas to the electric dust collector. After that, the waste gas will be purified by the electric dust collector and drained to the air.

Quality control system

![]()

![]()

After-sales service

Implementing the concept of pre-sale, in-sale and after-sale service:

1 Pre sale service:

Introducing products and related processes to users,Production Line Scheme and Technical Advantage,Providing pre-project technical advisory services,Customized Production Line Technical Solution for Customers.

2 Sale service:Manufacture excellent products for users,Provide customers with confidence in product quality.

Test:Strengthening Process Inspection and Intermediate Control,Strict Inspection System,Guarantee product quality,Providing quality products.

Train:Arrange experienced engineering technicians for training and guidance

install:Delegate engineers and technicians with experience in installation and commissioning to the site for installation and commissioning guidance,After customer acceptance is satisfactory,Qualified user opinion reports must be obtained.

3 After-sale service:

Regular guidance to users for product maintenance and maintenance,Free guidance for user installation,commissioning and product maintenance.Upon receipt of user failure handling requirements,Give maintenance advice within 24 hours.

Customer satisfaction is our constant pursuit, Always put the interests of customers first.

Certificate

![]()

![]()

![]()