-

Highlight

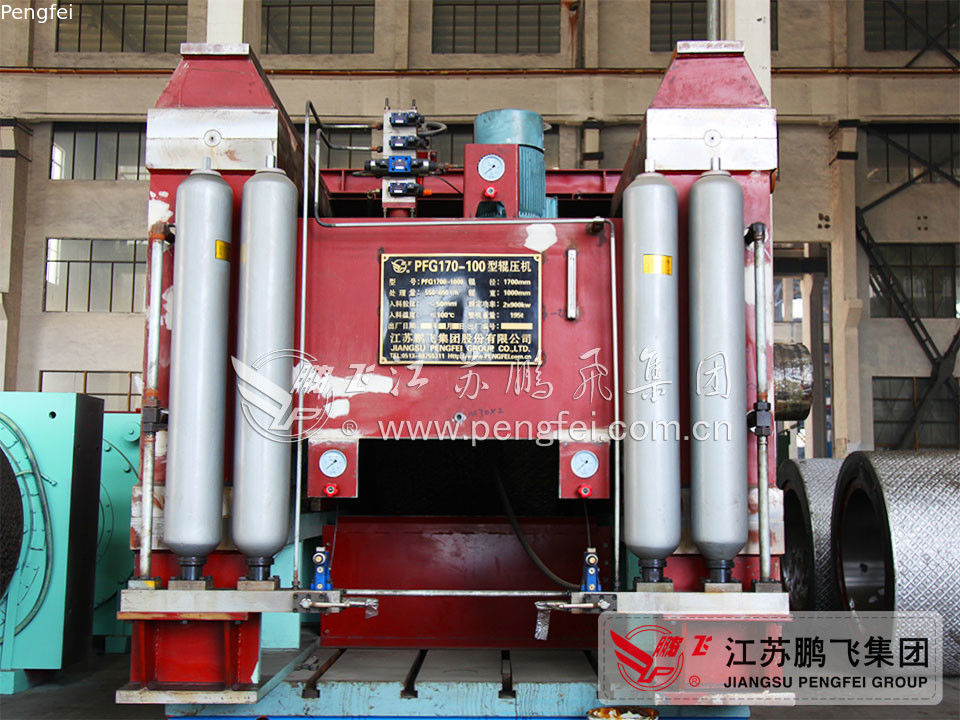

PFG Cement Production Plant

,2000kW Cement Production Plant

,Pengfei Cement Rotary Kiln

-

RollerTwo Rollers

-

Power250kW-2000kW

-

ProcessDry Process

-

Control MethodAutomatically Control

-

Warranty PeriodOne Year

-

After-sales ServiceYes

-

Working Hours24hours

-

Working Days300 Days-330days

-

Working Rate95%

-

Place of OriginJiangsu

-

Brand NamePengfei

-

CertificationCE,ISO

-

Model NumberPFG

-

Minimum Order Quantity1 set

-

PriceUSD400000-USD8000000

-

Packaging DetailsAll the packing is suitable for the ocean transporting and inland transporting,1.The kiln shell is transported in 6 sections. 2.The supports is packed on the cushion.3. the small parts is packed in wooden box and iron frame.4.there will be shipping mark on

-

Delivery Time180 days

-

Payment TermsL/C, T/T,CASH

-

Supply Ability1 SET PER 180days

PFG120-60 Pengfei Raw Material Cement Production Plant

PFG120-60 Pengfei Raw Material Cement Production Plant

We can produce the roller press from roller with max diameter 1200mm to 2000mm,the treating capacity is from 115t/h to 1250tph. The erected power is from 2*250kW to 2*2000kW. Such roller press win a lot of clients in domestic and foreign clients.we have sold to more than 100 clients in domestic area.Like the biggest cement group Huaxin group. We have exported to foreign clients like we export diameter 1800x1200 and dia 1600x1400 to Alacem cement plant in Kazakstan for 3200tpd cement plant. Export dia 1400x800 to KHOUNKHAM GROUP in....Export two sets of dia 1200x600 to Vietnam, export diameter 1400x800 to Algeria cement plant for 3000tpd cement plant.export South America Bolivia Cement projects,diameter 1600,export Pakistan PLC Cement plant diameter 1400mm.

| Content | Unit | Parameter |

| 1 Type | PFG-12060 | |

| 2 Diameter of roller | mm | 1200 |

| 3 Roller width | mm | 600 |

| 4 Through capacity | t/h | 110~165 |

| 5 Required comprehensive moisture | % | ≤3 |

| 6 Average product finess | ||

| ≤2mm | 70% | |

| ≤0.08mm | ≤25% | |

| 7 Inlet size/Max | mm | ≤60 |

| 8 Max material feeding temperature | ℃ | 100 |

| 9 Roller shaft speed | m/s | 1.47 |

| 10 Max forcing of roller | kN | 4200 |

| 11 Max material feeding temperature | ℃ | 100 |

| 12 Drive power | kW | 2×280 |

| 13 Mechanical data | ||

| 13.1 Main frame | ||

| Material | Q235B | |

| Heat treatment | Annealing treatment for whole | |

| Ultrasonic | Ultrasonic |

The main parts of roller press are two rollers one fixed roller, one moveable roller. Those two rollers will be pressurized by the hydraulic system ,once the material fall into the gap between those two rollers. They will be grounded into cake type by the high pressure. In those cake type material, there are lots of powders.the materials enter into ball mill without roller press system is 25mm,but now with pregrinding system, the material entering into the ball mill will be less than 1.5mm,so that in the next step ball mill grinding. It is easier for ball mill to grind the fine material, and the capacity is higher than single ball mill system. the most important of the parts are the rollers. The wear resistant layer of the rollers have two types in our company, one is wear resistant stud for the higher resistant material, like iron ore in metallurgy industry.one is hardfacing ,our hardfacing can be welded by imported material or domestic material ,it depends on your requirements.but the wear resistant stud type roller lifetime is longer than hardfacing layer roller.wear resistant stud type roller ,lifetime can be around 4 years, hardfacing layer is around just 8000hours.once worn, the roller press shall be stopped to make hardfacing again. Of course .the stud type roller price is higher than the hardfacign roller.

The pregrinding system also consists of V-type seperator

The V-shaped separator is a new type of powder separator. It is generally matched with a roller press to form various roller powder grinding systems. The V-shaped powder separator breaks up and classifies the cake pressed by the roller press, and can also dry the materials according to the process requirements. The appearance of the V-shaped separator has brought a new life and vitality to the rolling mill system. In order to meet the different requirements of different technological schemes on the material quantity and fineness of the V-shaped separator. The particle size of V-PF series powder separator is generally less than 0.2mm, and the fineness of the particles can be changed by adjusting the air volume and the direction of the blade.

The V-PF type powder separator is a static powder separator that is completely dispersed by gravity and separated by wind force. It is used to separate non-viscous and low-moisture materials. It can also be used in addition to the roller mill system. Coarse grinding or coarse powder separation process line.

When the moisture of the material to be sorted is heavy, hot air can be blown through the air inlet of the powder separator to dry it.

In order to ensure the function of the powder separator, the wind power of the air circulation system must be strictly controlled to reduce the air leakage at the feed and return ports, and make the feed distribution of the powder separator even.

We can produce the V-PF type seperator with air volume from 140000m3/h to 330000m3/h.

If you choose our company on the pre-grinding system, we will make the process calculation and select the right Seperator and roller press for you.

Workshop

![]()

![]()

The specification of roller press

| 13.2 Roller shaft | ||

| Structure type | Forged | |

| Material | 45# | |

| Heat treatment | Hardening and tempering | |

| Hardness | HV | 235±20 |

| Ultrasonic | Ultrasonic,Magnetic powder | |

| Cooling way | Water cooling | |

| 13.3 Roller surface | ||

| Material | Wear resistance alloy hardfacing | |

| Hardness of roller surface | HRC | 58~62 |

| Lifetime for onetime/lifetime after hardfacing | h | 8000/2000 |

| Guarantee precondition of lifetime for one time | No bigger material and metal | |

| 13.4 Bearing | ||

| Type | 23296CAK/W33 | |

| Lubricating system | Grease lubrication | |

| Supplier | DYZV | |

| 13.5 Bearing base | ||

| Material | ZG230-450 | |

| Temperature test element of bearing | Yes | |

| 13.6 Main drive unit | ||

| Motor | ||

| Type | Y450-6 | |

| Rated power | kW | 280 |

| Voltage | V | 380 |

| Speed | rpm | 744 |

| Supplier | Beide Simens | |

| Gear box | ||

| Type | XGF38M | |

| Rated speed ratio | 31.5 | |

| Supplier | Hubei Jujing | |

| 13.7 Supporting unit for torsion | COMBINED TYPE TORISION TYPE SUPPORTS | |

| 13.8 Feeding unit | ||

| Material | Wear ressitance steel plate HARDOX500 | |

| 13.9 Hydraulic system | ||

| Rated work pressure/Max pressure | bar | 160 |

| Oil cylinder type | mm | Φ320 |

| Oil cylinder manufacture | WUXI CHINA | |

| Main element supplier | SHANGHAI CHINA | |

| 13.10 Lubrication system for grease | ||

| 13.11 Lubrication unit for gear box | ||

| 13.12 Detecting unit | ||

| Displacement detection | ||

| Type | HKWDC-80L | |

| Range | 0~80mm | |

| Output | 4~20mA | |

| Quantity | 2 sets | |

| Tempreature test for main bearing | ||

| Type | WZPM-201 | |

| Graduation | Pt100 | |

| Range | 0~300℃ | |

| Quantity | 8个 | |

| Pressure test for hydraulic system | ||

| Range | 0~20MPa | |

| Output | 4~20mA | |

| Supplier | Germany EMB | |

| Quantity | Set | 2 |

| 13.13 Control panel | Set | 1 |

| Electrical element | SCHNEIDER CHINA | |

| PLC Supplier | Simens | |

| 13.14 Equipment weight | t | 70 |

![]()