-

Highlight

Dia3.5 Ball Mill In Cement Plant

,7m Ball Mill In Cement Plant

,7m Cement Plant Machinery

-

Capacity10tph-150tph

-

Shell MaterialQ235A

-

Working DaysContinously Working

-

Working Hours24hours

-

Place of OriginJiangsu,China

-

Brand NamePengfei

-

CertificationCE,ISO

-

Model NumberΦ2.2,Φ2.4Φ3,Φ3.2,Φ3.5,Φ3.8

-

Minimum Order Quantity1 set

-

PriceUSD250000-USD4000000

-

Packaging DetailsAll the packing is suitable for the sea worthy packing and inland packing 1.the heavy machinery can be bolted on the cushion, the equipments and parts easy to be corrosion is packed in wooden box. the liners and etc is packed in the iron frame.2.the differ

-

Delivery Time120 days

-

Payment TermsL/C,T/T

-

Supply Ability1 SET+120days

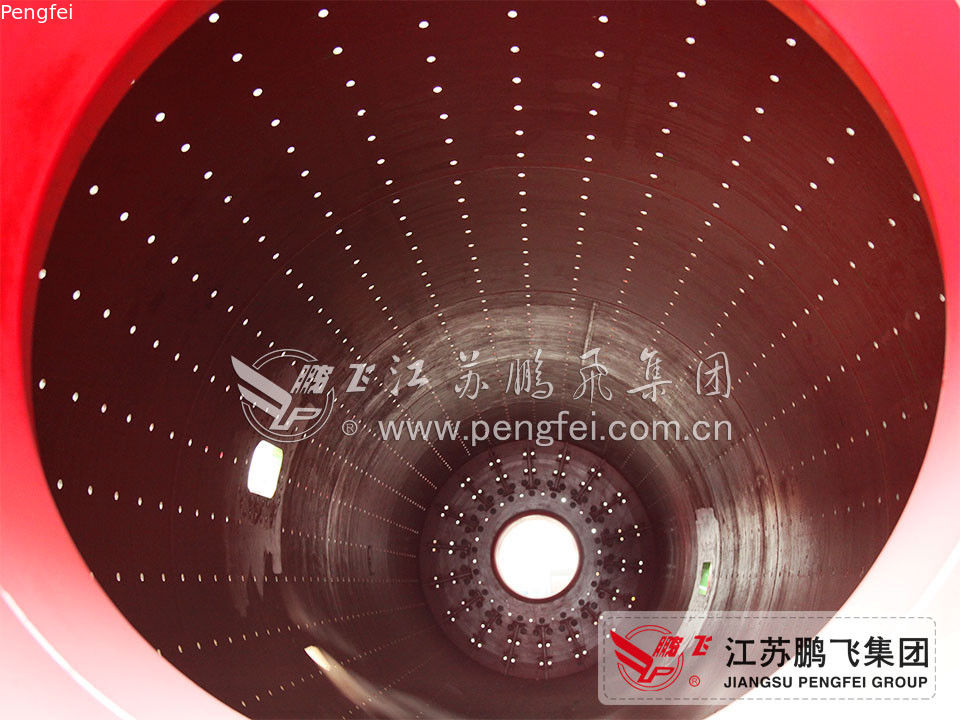

Dia3.5 7m Dry process ball mill in cement plant

Dia3.5 7m Dry Process Ball Mill In Cement Plant

Wet ball mill

Ball mill mainly consists of feeding part, discharging part, gyre part, transmission part (decelerated machine, small transmission gear, motor, electric control) and so on. The hollow axis adopts cast steel, the lining plate can be replaced, the big gyre gear is made of forging rolling gear, and there is lining plate in the cylinder body, which has favorable abrasion resistance. The ball mill has the features of stable running and reliable working.

Structural Feature of Ball Mill Purpose

The ball mill is widely used in such production industries as cement, silicate product, new building materials, corhart, chemical engineering, nonferrous and black metal, mineral processing, glass and ceramic, etc. It is used for grinding various ore and other grindable materials dry or wet

The client list of ball mill

| Sr. no | Name of projects |

Equipment

|

Qty |

| 1 | Vietnam Kaisa Cement Co,Ltd | φ4.8×13.5m | 2units |

| 3 | Vietnam Qingshan Cement Co,Ltd | φ4.8×13.5m | 1unit |

| 4 | Vietnam Kaisa Cement Co,Ltd | φ4.6×13m φ4.0×13m | 1unit/2units |

| 5 | Chongqing Tongli Technology Engineeing Co,Ltd | φ4.6×13m/φ3×12m | 1unit/2units |

| 6 | Sudan Atbara Cement Co,Ltd | φ4.6×13.5m | 3units |

| 7 | Hefei Cement Research Design Institute | φ4.6×13.5m | 3units |

| 8 | Sichuan Emeishan Cement Co,Ltd | φ4.6×13m/φ4.2×13m | 1unit/2units |

| 9 | Sichuan Emeishan City Fertilizer Factory | φ4.6×(9.5+3.5)m | 1unit |

| 10 | Fujian longyan chunchi cemet group co,Ltd. | φ4.2×13m | 1unit |

| 11 | Hunan Hongli Cement Co,Ltd | φ4.2×13m | 1unit |

| 12 | Leiyang City Jindun Cement Co., Ltd. | φ4.2×13m | 1unit |

| 13 | Shanxi Ankuang Jianghua Cement Co., Ltd. | φ4.2×13m | 1unit |

| 14 | Shandong Juzhou Cement Co., Ltd. | φ4.2×13m | 1unit |

| 15 | Shichuang Emeishan City Phosphatic Fertilizer Factory | φ4.2×13m | 2units |

| 16 | Pakistan PLD Cement Co., Ltd. | φ4.2×13m | 2units |

| 17 | Baogang Yuanli Metallurgical Slag Micropowder Co., Ltd. | φ4.2×13m | 2units |

| 18 | Henan dadi Cement Co,,Ltd | φ4.2×12.5m | 2units |

| 19 | Handan Sinao Construction Co., Ltd. | φ4.2×12.5m | 1unit |

| 20 | Zhejiang Longyou Qinglongshan Cemet Co,,Ltd | φ3.8×7.5m/φ3×11m | 2units/4units |

| 21 | Shanxi Taiyuan Guangdongshan Cement Co., Ltd. | φ3.8×12m | 1unit |

| 22 | Chongqing Runjiang Cemet Co,,Ltd | φ3.8×13m | 2units |

| 23 | Guangdong Aofeng(Luoding) Cemet Co,,Ltd | φ3.8×13m | 2units |

| 24 | Vietnam Huanglong 1000TPD Production Line | φ3.8×13m | 1unit |

| 25 | Ninxia Pingluo Hengda Cement Co., Ltd. | φ3.8×13m | 1unit |

| 26 | Zhangzhou Zijin Building Material Co., Ltd. | φ3.8×13m | 2units |

| 27 | Guizhou Liuzhi Gongkuang Runan Cement Co., Ltd. | φ3.8×13m | 1unit |

| 28 | Eritrea GEDEM | φ3.8×13m | 1unit |

| 29 | Pakistan PLC Cement Co., Ltd. | φ3.8×13m(hollow shaft) | 2units |

| 30 | Pakistan PLEF Cement Co., Ltd. | φ3.8×13m(hollow shaft) | 3units |

| 31 | Xinjiang Precise Cemet Co,,Ltd. | φ3.8×13m(hollow shaft) | 1unit |

| 32 | Hunan I & E Company | φ3.8×13m | 2units |

| 33 | Neimenggu Yinli Jindong Cement Co., Ltd. | φ3.8×13m | 1unit |

| 34 | Fujian Longyan Zijin Group Co,,Ltd | φ3.8×13m(hollow shaft) | 1unit |

| 35 | China Combination Cemet Co,,Ltd | φ3.8×13m(hollow shaft) | 3units |

| 36 | Shanxi Dongshan Cement Co., Ltd. | φ3.8×13m | 1units |

| 37 | Daqing Mengxi Cement Co., Ltd. | φ3.8×13m(double sliding shoe) | 2units |

| 38 | Arongqi Menxi Cement Co., Ltd. | φ3.8×13m(hollow shaft) | 2units |

| 39 | Yili Nangang Building Material Co., Ltd. | φ3.8×13m | 1unit |

| 40 | Fubei Wudang Cement Co., Ltd. | φ3.8×13m | 2units |

| 41 | Myanmar Dragon Cement Factory | φ3.5×11.5m | 1unit |

| 42 | Heilongjiang Haerbin Taihang Yinlong Cement Plant | φ3.5×8m | 1unit |

| 43 | Tiancheng Chemical Co., Ltd. | φ3.5×10m | 2units |

| 44 | Guizhou Rongsheng(Group) Building Material Co., Ltd. | φ3.5×10m/φ3.5×13m | 2units/2units |

| 45 | Xinjiang Xinlong Cement Co., Ltd. | φ3.5×11.5m | 1unit |

| 46 | Xinjiang International Engineering Technology Co., Ltd. | φ3.5×11.5m | 2units |

| 47 | Fuzhou Queli Cement Co., Ltd. | φ3.5×13m | 1unit |

| 48 | Chengdu International Economic & Technical Cooperation Co., Ltd. | φ3.5×11.5m | 1unit |

| 49 | Huizhe Dianbai Trade Co., Ltd. | φ3.5×11m | 1unit |

| 50 | Shanxi Tongzhou Mianyi Cement Co., Ltd. | φ3.5×11m | 1unit |

| 51 | Myanmar HTCT | φ3.2×11m | 1unit |

| 52 | Guangxi Yufeng Cement Co., Ltd. | φ3.2×11m | 2units |

| 53 | Guangxi Pingnan Guidan Cement Co., Ltd. | φ3.2×13m | 1unit |

| 54 | Shanxi Nifeng Hongda Cement Co., Ltd. | φ3.2×13m | 1unit |

| 55 | Xiameng Lute Lingshi Building Material Co., Ltd. | φ3.2×13m | 1unit |

| 56 | Henan Lingshan Cement Co., Ltd. | φ3.2×13m | 1unit |

| 57 | Sunchangjiang | φ3.2×13m | 1unit |

| 58 | Liguangyou | φ3.2×13m | 1unit |

| 59 | Fanzhitian | φ3.2×13m | 1unit |

| 60 | Wuhan Xinlingyun Cement Co., Ltd. | φ3.2×13m | 1unit |

| 61 | Wuhan Shengda Material Co., Ltd. | φ3.2×13m(slag mill) | 1unit |

| 62 | Suzhou Longquan Cement Co., Ltd. | φ3.2×13m | 1unit |

| 63 | Changzhi Kebao Cement Co., Ltd. | φ3.2×13m | 1unit |

| 64 | Bayan Zuoer Tuanyang Cement Co., Ltd. | φ3.2×13m | 1unit |

| 65 | Zhongjian Sanjun Commodity Concrete Supply Station | φ3.2×13m | 1unit |

| 66 | Xi’an Huxian Qiangwan | φ3.2×13m | 1unit |

| 67 | Yunnan Luoping Sanhai Cement Co., Ltd. | φ3.2×(7+2)m | 2units |

| 68 | Yunnan Pengcheng Gongmao Co., Ltd. | φ3.2×13m | 2units |

| 69 | Yunnan yingjiang Yunhan Cement Co., Ltd. | φ3.2×13m | 2units |

| 70 | Yunnan Simao Jianfeng Cement Co., Ltd. | φ3.2×7m/φ3×11m | 1unit/2units |

| 71 | Jilin Songliao Cement Co., Ltd. | φ3.2×13m | 1unit |

| 72 | Jilin Yanbian Miaoling Cement Co., Ltd. | φ3×11m/φ3.4×8.5m | 2units/1unit |

| 73 | Jinlin Dequan Cement Co., Ltd. | φ3.2×13m | 2units |

| 74 | Jinlin Siping Hongzui Cement Co., Ltd. | φ3.2×13m φ2.4×13m | 1unit/2units |

| 75 | Jinlin Shiling Cement Co., Ltd. | φ3.2×13m | 1unit |

| 76 | Zhejiang Shaoxing Zhaoshang Co., Ltd. | φ3.2×13m/φ3.5×10m | 2units |

| 77 | Zhejiang Shaoxing Huijishan Cement Co., Ltd. | φ3.2×13m | 1unit |

Dry process ball mill

Model PMG Series high efficient ball mill has been designed with the merits of open circuit grinding system and important renovations on traditional ball mills,besides they have all the good advantages of open circuit mills,production capacity has been raised sustantially,product becoms super fine and blaines have been increased,it has provided a new type of grinding equipment for producing high strength grade cement with high output and super finess.

Model PMG ball mill has adopted special intergrate diaphragm and discharge grate to adjust material levels of every chamber so as to increase air ventilation and improve conditions inside mill,meanwhile it has also used new type of lining plate,regulated mill rotation speed,optimized design of pinion&girth gear and lubricating parameters of bearings sso as to increase its operational stability,use life and grinding efficiency.

After being put into practice,it is proved that its output has been increased about 20% and unit product power consumption has been reduced 10%-12% down under the conditions that other parameters have not been changed by comparision to other same sized ball mill,while being operated in open circuit,specific surface of cement could be reached up to 320cm/kg performance of it is up to national advaned standard,it has been awarded as well-known brand product of China building material industry,well know brand product of Jiagnsu Province,state star plan products,appointed manufacture of National building material machinery industry etc.

Coal mill

Coal mill is the main equipment of cement plant and is used for drying and grinding coal pulverized.

It is made up of the feede device,main bearing,rotary part,driving device,discharge device,high pressure starting device and lubricating system

The coal mill features rational structure and high grinding efficiency.it is an ideal equipment for pulverized coal preaparation.

The Scope of ball mill

| 1,Rotary part | 1set |

| Shell | 1pcs |

| Inlet and outlet hollow shaft | 2pcs |

| Inlet and outlet spiral shell | 2pcs |

| Double diaphragm unit | 1set |

| Liners and bolts | 1set |

| 2,Main bearing (Include shaft bush) | 2sets |

| 3,Inlet unit | 1set |

| 4,Outlet unit(Include connection pipe) | 1set |

| 5,Drive unit | 1set |

| Main motor YRKK710-8 1250kW 3300V(Chongqing motor manufacture) | 1pcs |

| Main gear box MFY125A (Include thin oil station)(NGC) | 1pcs |

| Auxiliary drive unit MJM560 | 1set |

| Diaphragm coupling MFY120L | 1set |

| Base frame for drive unit | 1pcs |

| 6,Thin oil station GYXZ-40A | 2sets |

| 7,Foundation bolts | 1set |

| 8,Control cabinet (HP control,LP start,thin oil station control) | 1pcs |

The structure of ball mill

Workshop Photos

![]()