-

Highlight

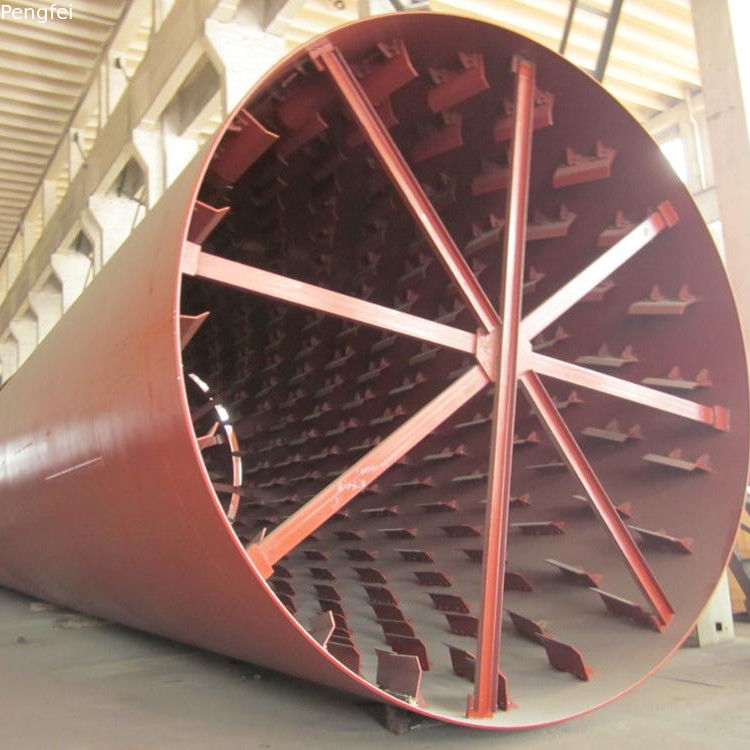

90 tph Rotary Drum Dryer Machine

,Q235 Rotary Drum Dryer Machine

,90 tph Rotary Kiln Dryer

-

MaterialQ235

-

ColorAs Per Your Requirements

-

ProcessDry Process

-

Control MethodAutomatically Control

-

Voltage380V,10kV,11kV,6kV

-

WeightAs Per Process

-

PackingSeaworthy Packing

-

TypeHorizontal

-

Place of OriginJIANGSU,CHINA

-

Brand NamePengfei

-

CertificationCE,ISO

-

Model Number3.0*28m

-

Minimum Order Quantity1 set

-

PriceUSD200000-USD700000

-

Packaging DetailsAll the packing is suitable for the ocean transporting and inland transporting,1.The kiln shell is transported in 6 sections. 2.The supports is packed on the cushion.3. the small parts is packed in wooden box and iron frame.4.there will be shipping mark on

-

Delivery Time180 days

-

Payment TermsL/C, T/T

-

Supply Ability1 SET PER 180days

Automatically Control ISO 90 Tph Rotary Drum Dryer Machine

Automatically Control ISO 90 Tph Rotary Drum Dryer Machine

Our company is the biggest manufacture base for the rotary kiln we have manufactured the vertical kiln from 1983, and rotary kiln from 1994,till now we have already manufactured for 26 years.Our chairman Mr Wang Jiaan make a lot of investment on arranging technical team to research, cooperate with the famous research institute and college for many years to improve the technology of our rotary kiln.

Main parts and materials:

| 1,Shell | Q235B |

| 2,Tyre | ZG45 |

| 3,Girth gear | ZG45 |

| 4,Supporting roller | ZG55 |

| 5,Supporting roller shaft | 45 steel forgedpiced |

| 6,Pinion | 40Cr |

| 7,Motor | YCT355-4B |

| 8,Reducer | ZL100-22.4 |

High efficiency energy saving rotary dryer

Technical parameters

1,Shell inner diameter φ3.2m

2,Shell length 20m

3,Productive capacity ~85t/h(original moisture 16%,final moisture 8% of clay)

4,Inclination 3.5%

5,Support No. 2

6,Rotating speed 8.4-3.85r/min

7,Motor model YCT355-4B power 75kW rotating speed 1320-600r/min

8,Reducer model ZL100-22.4 center distance 1000 speed ratio 22.4

9,Equipment weight 108t

Scope of supply

| 1,Shell part | 1 piece |

| 2,Girth gear | 1 set |

| 3,Supporting device | 2 sets |

| 4,Thrust roller device | 1 set |

| 5,Drive unit | 1 set |

| 6,Anchor bolts |

1 set |

![]()

Company workshop

![]()

![]()

Company Branches

Main workshop

![]()

After sales service

Service:

1. We offer perfect after-sales services to our customers throughout the world. Our skilled and experienced after-sales service staff can stay in your factory for equipment assembly and debugging.

2. We also have emergency after-sales services to solve various operation problems and equipment faults existing in the production processes. We will send our technicians to your production sites to solve your problems.

3. We will strictly observe the set delivery time, and will never make excuses to delay the delivery time.