-

Highlight

300 tpd Rotary Lime Kiln

,90m Rotary Lime Kiln

,90m Cement Rotary Kiln

-

Capacity300tpd To 6000tpd

-

ColorAs Per Your Requirements

-

TypeHydraulic Type

-

Place of OriginJiangsu,China

-

Brand NamePengfei

-

CertificationCE,ISO

-

Model NumberΦ2.8---Φ6.0

-

Minimum Order Quantity1 set

-

PriceUSD400000-USD3000000

-

Packaging DetailsAll the packing will be suitable for sea and road transporting2.the heavy machine will be bolted on the cushion. 3.The easy damaged parts will be packed in the wooden box. 4.The iron parts will be packed in the iron railing,iron box,iron frame,5.some parts

-

Delivery Time180 days

-

Payment TermsL/C,T/T

-

Supply Ability1 set per 180 days

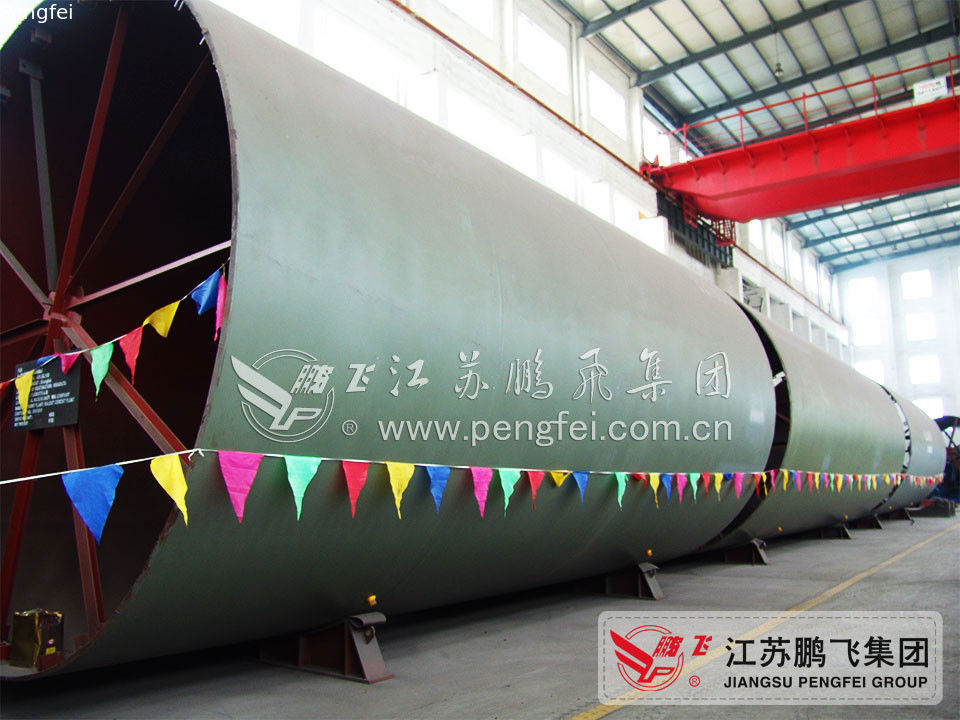

Φ4.0 90m Burning Nickel Ore Rotary Lime Kiln

WELCOME TO JIANGSU PENGFEI GROUP CO.,LTD

Φ4.0 90m Burning Nickel Ore Rotary Lime Kiln

Now our rotary kiln are the leaders for rotary kiln in cement plant with capacity from 300tpd,700tpd,800tpd,1000tpd,1200tpd,1500tpd,2000tpd,2500tpd,3000tpd,3500tpd,4000tpd,5000tpd, 8000tpd ,lime plant capacity from 300tpd to 1200tpd.300tpd,400tpd,600tpd,800tpd,1000tpd,1200tpd.Nickel ore plant from 50000tons 150000tons.our such rotary kiln with advanced technology and high automation level can increase the running rate 3-5%,production has been raised by 5-10%, and heat consumption has been reduced 15% down. Till now we have sold to more than 200 hundred clients in the domestic clients in such filed and more than 100 hundred clients in foreign countries. we also cooperate European countries for the rotary kiln manufacturing.

Kiln shell, we buy the steel plate from Bao steel, Wugang steel, the first-class steel plant in China to guarantee the quality because the shell shall resist high temperature. We have the automatic cutting machine, rolling machine which can roll 120mm thick, and skilled welders to weld the shell section. Different instruments to inspect the welding of shell.Ultrasonic test and magnetic powder test to check where is the crack and the crack position..

- The size of rotary kiln

-

Application Quick lime plant Equipment name Ф3.2×50m rotary kiln 1. Technical parameter Capacity t/h 300tpd Slope % 3.5 Supporting No. 2pier Speed Main speed r/min 0.3~3.0 Drive type Single drive Main drive motor Type(VFD Motor) ZSN4-280-091B Power kW 110kW Rated speed r/min 1000 Armature voltage 440V Exciting voltage 180V Speed adjusting range r/min 100-1000 Protection grade IP54 Auxiliary motor Type: Y160M-4B Power kW 11 Rated speed r/min 1460r/min Rated voltage V 110V Rated speed r/min 0-2000r/min Auxiliary gear box Type ZSY160-31.5 Rated power Main drive gear box Type YNS1110-63VIBL Total center distance 1110 Total nominal speed ratio mm 63 2. Main part Shell pcs Q235-B Material Q235-B or 20g Tyre pcs Material ZG310-570 Hardness >180 Qty 2Pcs Girth gear pcs Material ZG310-570 Hardness HB=200 Qty 1Pcs Sealing at kiln inlet Steel sealing Qty set 1 Sealing at kiln outlet Steel sealing Qty set 1 Supporting roller part Supporting roller ZG340-640 Hardness HB>190 Qty Pcs 2 Supporting roller shaft Material 45# Hardness HRC45-48 Qty 2Pcs Thrust roller supporting unit Qty set 1 Supporting roller Supporting roller shaft Thrust roller Material ZG340-640 Hardness HB>190 Bearing base of thrust supporting roller Qty 1pcs Oil pump station and control panel Type NC-14 Qty pcs 1 Pinion part Pinion Material 35SiMn Hardness HB>207-269 Qty pcs 1 Pinion shaft Material 35CrMo Hardness HB>217-265 Qty pcs 1 -

Workshop

-