-

Highlight

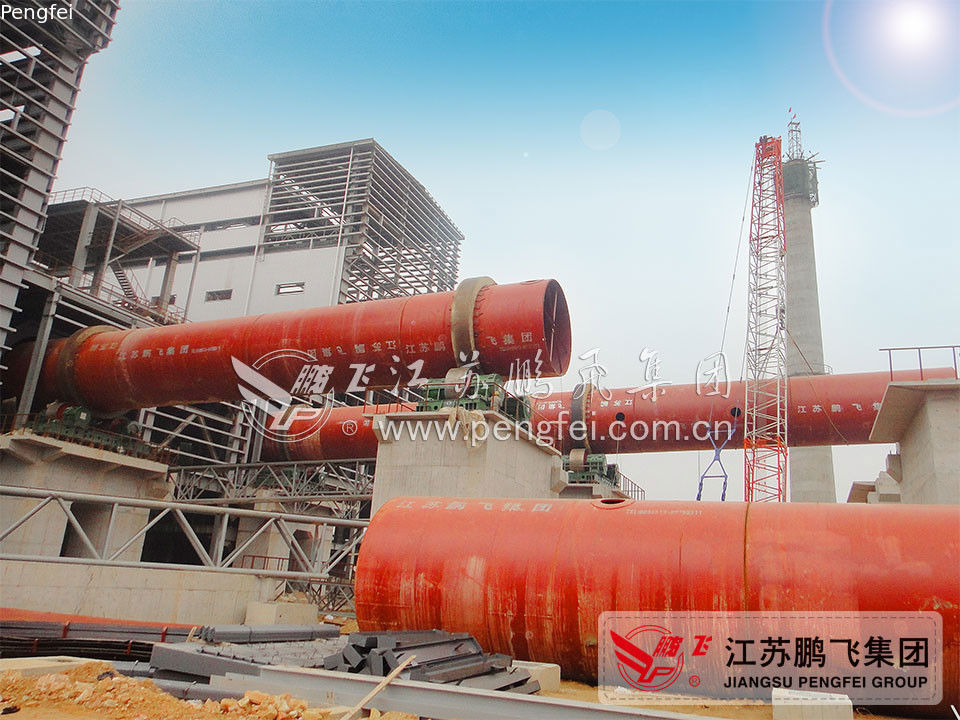

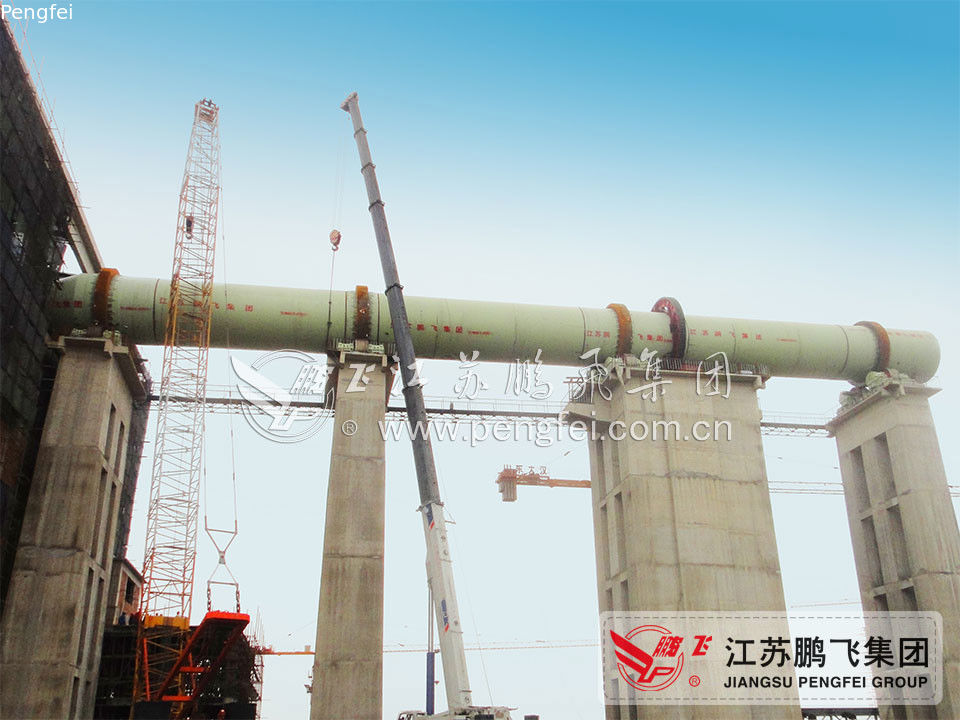

380V Rotary Kiln System

,9.6m Rotary Kiln System

,9.6m Rotary Kiln Cement Plant

-

ConditionNew

-

ColorRed,grey

-

Working Days330 Days

-

Working Rate95%

-

After Sales ServiceYes

-

Waranty PeriodOne Year

-

Voltage380V,10kV,6.6kV,11kV

-

MotorAC Motor

-

Place of OriginJiangsu,China

-

Brand NamePengfei

-

CertificationCE,ISO

-

Model NumberΦ2.8---Φ6.0

-

Minimum Order Quantity1 set

-

PriceUSD400000-USD3000000

-

Packaging DetailsAll the packing will be suitable for sea and road transporting2.the heavy machine will be bolted on the cushion. 3.The easy damaged parts will be packed in the wooden box. 4.The iron parts will be packed in the iron railing,iron box,iron frame,5.some parts

-

Delivery Time180 days

-

Payment TermsL/C,T/T

-

Supply Ability1 set per 180 days

Φ2.6 Dry Process 9.6m Waste Treatment Rotary Kiln System

WELCOME TO JIANGSU PENGFEI GROUP CO.,LTD

Φ2.6 Dry Process 9.6m Waste Treatment Rotary Kiln System

The Kiln consists of kiln shell,supporting unit,hydraulic thrust rollers. drive unit,kiln inlet and outlet sealing unit,so please see the video of the rotary kiln.

We can design as per your requirements if you provide us the capacity or the size, we will calculate and choose one right type for you. The rotary kiln must be in good quality,because the rotary kiln shall be running for 24 hours. And once stop, it need three days to restart, time is money, So please choose Pengfei, because we have long history and much more experience on manufacturing and improving the rotary kiln.

Please see the video to know more about our company.

- Kiln shell, we buy the steel plate from Bao steel, Wugang steel, the first-class steel plant in China to guarantee the quality because the shell shall resist high temperature. We have the automatic cutting machine, rolling machine which can roll 120mm thick, and skilled welders to weld the shell section. Different instruments to inspect the welding of shell.Ultrasonic test and magnetic powder test to check where is the crack and the crack position.

- The supporting unit:the supporting unit can have two,three or four,normally cement plant rotary kiln have three, lime plant have two, nickel ore plant have four or more, it depends on length and other design index of the rotary kiln.

- Tyre, most of our tyre are castings tyre ,we have our own casting company branch, which branch can make castings maximum 190t.we can also do the forging tyre,so if you need the spare parts like tyre,please try to contact with me,we can produce as per your drawings

- Pads. Such pads is to avoid the temperature difference of the tyre inside and outside surface and eliminate the expansion and contraction of the tyre to extend its lifetime.

- Girth gear. We can produce spur gear, helical gear,so if you need the spare parts like girth gear with spur gear,helical gear or bevel gear,please try to contact with me,we can produce as per your drawings

- Spring plate: to connect the girth gear and shell.

- Hyraulic thrust roller: besideds the hydraulic thrust roller,there is also mechanical thrust roller which one does not use much more now. Such unit can push the tyre and supporting roller to be worn on the whole width to extend their lifetime.

- The sealing unit:Kiln inlet and kiln outlet. We have designed from graphite block sealing to fish scales sealing. Fish scales sealing is much more simple and convenient.now most of rotary kiln we adopt fish scales sealing.

The size of rotary kiln

| Model | Capacity(t/h) | Slope(%) | No of supports |

| Φ2.3x9 | 20 | 1.5 | 2 |

| Φ2.6x9.6 | 30 | 1.5 | 2 |

| Φ3x12.5 | 40 | 1.5 | 2 |

| Φ3.4x15 | 45-48 | 1.5 | 2 |

| Φ3.5x15 | 50 | 1.5 | 2 |

| Φ3.8x11 | 65 | 1.5 | 2 |

| Φ4.0x16 | 80 | 1.5 | 2 |

| Φ4.3x15.5 | 100 | 1.5 | 2 |

| Φ4.6x16.5 | 110 | 2 | 2 |

Our company is the biggest manufacture base for the rotary kiln we have manufactured the vertical kiln from 1983, and rotary kiln from 1994,till now we have already manufactured for 26 years.Our chairman Mr Wang Jiaan make a lot of investment on arranging technical team to research, cooperate with the famous research institute and college for many years to improve the technology of our rotary kiln. From the wet process to dry process, from size around 2 meters to 6 meters.from cement plant other industry filed. From two piers to four piers.Now our rotary kiln are the leaders for rotary kiln in cement plant with capacity from 300tpd,700tpd,800tpd,1000tpd,1200tpd,1500tpd,2000tpd,2500tpd,3000tpd,3500tpd,4000tpd,5000tpd, 8000tpd ,lime plant capacity from 300tpd to 1200tpd.300tpd,400tpd,600tpd,800tpd,1000tpd,1200tpd.Nickel ore plant from 50000tons 150000tons.our such rotary kiln with advanced technology and high automation level can increase the running rate 3-5%,production has been raised by 5-10%, and heat consumption has been reduced 15% down. Till now we have sold to more than 200 hundred clients in the domestic clients in such filed and more than 100 hundred clients in foreign countries. we also cooperate European countries for the rotary kiln manufacturing.

The structure of rotary kiln

-

Workshop

-